NDFEB MAGNET

NdFeB magnet

Neodymium magnet (also known as NdFeB, NIB or Neo magnet) has high remanence, high coercivity and high energy product. It is called Magnet King.

NdFeB maagnets has good mechanical properties, easy to process into ring, round, square, arc and a variety of special-shaped products. It is widely used in new energy vehicles, wind power generation, industrial motors, consumer electronics, medical devices and other fields.

Now we are able to make NdFeB magnets grade from N35-N56, N35M-56M, N35H-N54H, N33SH-N52SH, N33UH-N50UH, N33EH-N48EH, N30AH-N45AH.

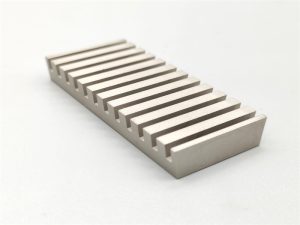

We make different shape of NdFeB magent

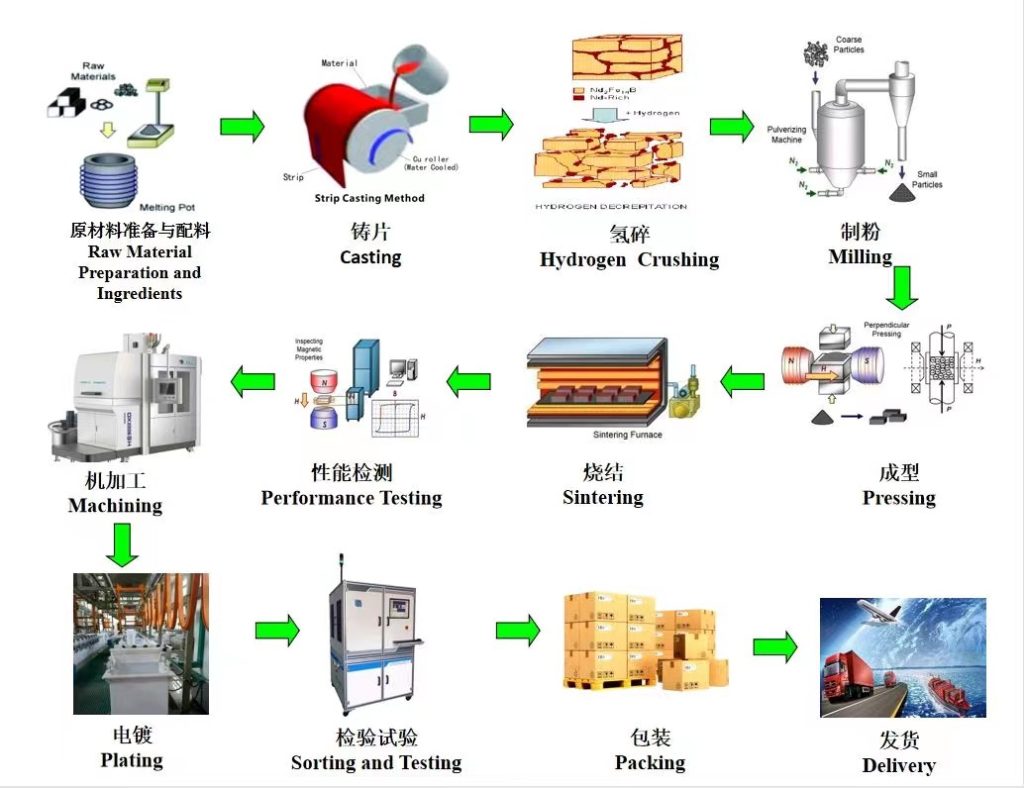

Manufacturing Process of NdFeB Magnet

NdFeB Magnet Performance Table

| Grade | (Br)Remanence | (Hcj)Min Intrinic Coercivity | (Hcb)Min Coercivity | (BH)maxMax Energy Product | Density | Max WorkingTems | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| T | kGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | g/cm3 | ℃ | |

| N56 | 1.47-1.51 | 14.7-15.1 | 876 | 11 | 836 | 10.5 | 414-454 | 52-57 | 7.5 | 80 |

| N54 | 1.45-1.49 | 14.5-14.9 | 955 | 12 | 836 | 10.5 | 406-437 | 51-55 | 7.5 | 80 |

| N52 | 1.42-1.46 | 14.2-14.6 | 955 | 12 | 836 | 10.5 | 390-422 | 49-53 | 7.5 | 80 |

| N50 | 1.39-1.44 | 13.9-14.4 | 955 | 12 | 860 | 10.8 | 374-406 | 47-51 | 7.5 | 80 |

| N48 | 1.37-1.43 | 13.7-14.3 | 955 | 12 | 860 | 10.8 | 358-390 | 45-49 | 7.5 | 80 |

| N45 | 1.32-1.37 | 13.2-13.7 | 955 | 12 | 860 | 10.8 | 342-366 | 43-46 | 7.5 | 80 |

| N42 | 1.28-1.32 | 12.8-13.2 | 955 | 12 | 860 | 10.8 | 318-342 | 40-43 | 7.5 | 80 |

| N40 | 1.25-1.28 | 12.5-12.8 | 955 | 12 | 860 | 10.8 | 302-326 | 38-41 | 7.5 | 80 |

| N38 | 1.22-1.25 | 12.3-12.5 | 955 | 12 | 860 | 10.8 | 287-310 | 36-39 | 7.5 | 80 |

| N35 | 1.17-1.22 | 11.7-12.2 | 955 | 12 | 860 | 10.8 | 263-287 | 33-36 | 7.5 | 80 |

| N33 | 1.13-1.17 | 11.3-11.7 | 955 | 12 | 836 | 10.5 | 247-271 | 31-34 | 7.5 | 80 |

| N30 | 1.08-1.13 | 10.8-11.3 | 955 | 12 | 796 | 10 | 223-247 | 28-31 | 7.5 | 80 |

| 56M | 1.46-1.5 | 14.6-15 | 1035 | 14 | 995 | 12.5 | 406-446 | 51-56 | 7.5 | 100 |

| 54M | 1.44-1.49 | 14.4-14.9 | 1114 | 14 | 1035 | 13 | 398-438 | 50-55 | 7.5 | 100 |

| 52M | 1.42-1.46 | 14.2-14.6 | 1114 | 14 | 1035 | 13 | 382-422 | 49-53 | 7.5 | 100 |

| 50M | 1.39-1.44 | 13.9-14.4 | 1114 | 14 | 1035 | 13 | 374-406 | 47-51 | 7.5 | 100 |

| 48M | 1.37-1.42 | 13.7-14.2 | 1114 | 14 | 1027 | 12.9 | 358-390 | 45-49 | 7.5 | 100 |

| 45M | 1.32-1.37 | 13.2-13.7 | 1114 | 14 | 995 | 12.5 | 342-366 | 43-46 | 7.5 | 100 |

| 42M | 1.28-1.32 | 12.8-13.2 | 1114 | 14 | 955 | 12 | 318-342 | 40-43 | 7.5 | 100 |

| 40M | 1.25-1.28 | 12.5-12.8 | 1114 | 14 | 923 | 11.6 | 302-326 | 38-41 | 7.5 | 100 |

| 38M | 1.22-1.25 | 12.3-12.5 | 1114 | 14 | 899 | 11.3 | 287-310 | 36-39 | 7.5 | 100 |

| 35M | 1.17-1.22 | 11.7-12.2 | 1114 | 14 | 868 | 10.9 | 263-287 | 33-36 | 7.5 | 100 |

| 33M | 1.13-1.17 | 11.3-11.7 | 1114 | 14 | 836 | 10.5 | 247-271 | 31-34 | 7.5 | 100 |

| 30M | 1.08-1.13 | 10.8-11.3 | 1141 | 14 | 796 | 10 | 223-247 | 28-31 | 7.5 | 100 |

| 54H | 1.44-1.49 | 14.4-14.9 | 1353 | 17 | 1075 | 13.5 | 398-438 | 50-55 | 7.5 | 120 |

| 52H | 1.42-1.46 | 14.2-14.6 | 1353 | 17 | 1059 | 13.3 | 382-422 | 48-53 | 7.5 | 120 |

| 50H | 1.39-1.44 | 13.9-14.4 | 1353 | 17 | 1043 | 13.1 | 374-406 | 47-51 | 7.5 | 120 |

| 48H | 1.36-1.42 | 13.6-14.2 | 1353 | 17 | 1027 | 12.9 | 358-390 | 45-49 | 7.5 | 120 |

| 45H | 1.32-1.37 | 13.2-13.7 | 1353 | 17 | 995 | 12.5 | 342-366 | 43-46 | 7.5 | 120 |

| 42H | 1.28-1.32 | 12.8-13.2 | 1353 | 17 | 955 | 12 | 318-342 | 40-43 | 7.5 | 120 |

| 40H | 1.25-1.28 | 12.5-12.8 | 1353 | 17 | 923 | 11.6 | 302-326 | 38-41 | 7.5 | 120 |

| 38H | 1.22-1.25 | 12.3-12.5 | 1353 | 17 | 899 | 11.3 | 287-310 | 36-39 | 7.5 | 120 |

| 35H | 1.17-1.22 | 11.7-12.1 | 1353 | 17 | 868 | 10.9 | 263-287 | 33-36 | 7.5 | 120 |

| 33H | 1.13-1.17 | 11.3-11.7 | 1353 | 17 | 836 | 10.5 | 247-271 | 31-34 | 7.5 | 120 |

| 30H | 1.08-1.13 | 10.8-11.3 | 1353 | 17 | 796 | 10 | 223-247 | 28-31 | 7.5 | 120 |

| 54SH | 1.44-1.49 | 14.4-14.9 | 1592 | 20 | 1075 | 13.5 | 398-438 | 50-55 | 7.5 | 150 |

| 52SH | 1.42-1.46 | 14.2-14.6 | 1592 | 20 | 1059 | 13.3 | 390-422 | 49-53 | 7.5 | 150 |

| 50SH | 1.39-1.42 | 13.9-14.2 | 1592 | 20 | 1043 | 13.1 | 374-406 | 47-51 | 7.5 | 150 |

| 48SH | 1.36-1.4 | 13.6-14 | 1592 | 20 | 1035 | 13 | 358-390 | 45-49 | 7.5 | 150 |

| 45SH | 1.32-1.37 | 13.2-13.7 | 1592 | 20 | 995 | 12.5 | 342-366 | 43-46 | 7.5 | 150 |

| 42SH | 1.28-1.32 | 12.8-13.2 | 1592 | 20 | 955 | 12 | 318-342 | 40-43 | 7.5 | 150 |

| 40SH | 1.25-1.28 | 12.5-12.8 | 1592 | 20 | 939 | 11.8 | 302-326 | 38-41 | 7.5 | 150 |

| 38SH | 1.22-1.25 | 12.2-12.5 | 1592 | 20 | 907 | 11.4 | 287-310 | 36-39 | 7.5 | 150 |

| 35SH | 1.17-1.22 | 11.7-12.2 | 1592 | 20 | 876 | 11 | 263-287 | 33-36 | 7.5 | 150 |

| 33SH | 1.13-1.17 | 11.3-11.7 | 1592 | 20 | 844 | 10.6 | 247-271 | 31-34 | 7.5 | 150 |

| 30SH | 1.08-1.13 | 10.8-11.3 | 1592 | 20 | 804 | 10.1 | 223-247 | 28-31 | 7.5 | 150 |

| 48UH | 1.36-1.4 | 13.6-14 | 1910 | 24 | 1031 | 12.9 | 358-390 | 45-49 | 7.55 | 180 |

| 45UH | 1.32-1.36 | 13.2-13.6 | 1990 | 25 | 1003 | 12.6 | 324-366 | 43-46 | 7.55 | 180 |

| 42UH | 1.28-1.32 | 12.8-13.2 | 1990 | 25 | 971 | 12.2 | 318-342 | 40-43 | 7.55 | 180 |

| 40UH | 1.25-1.28 | 12.5-12.8 | 1990 | 25 | 923 | 11.6 | 302-326 | 38-41 | 7.55 | 180 |

| 38UH | 1.22-1.25 | 12.2-12.5 | 1990 | 25 | 907 | 11.4 | 287-310 | 36-39 | 7.55 | 180 |

| 35UH | 1.17-1.22 | 11.7-12.2 | 1990 | 25 | 860 | 10.8 | 263-287 | 33-36 | 7.55 | 180 |

| 33UH | 1.13-1.17 | 11.3-11.7 | 1990 | 25 | 852 | 10.7 | 247-271 | 31-34 | 7.55 | 180 |

| 30UH | 1.08-1.13 | 10.8-11.3 | 1990 | 25 | 812 | 10.2 | 223-247 | 28-31 | 7.55 | 180 |

| 45EH | 1.32-1.36 | 13.2-13.6 | 2308 | 29 | 1003 | 12.6 | 342-366 | 43-46 | 7.6 | 200 |

| 42EH | 1.28-1.32 | 12.8-13.2 | 2388 | 30 | 970 | 12.2 | 318-342 | 40-43 | 7.6 | 200 |

| 40EH | 1.25-1.28 | 12.5-12.8 | 2388 | 30 | 947 | 11.9 | 302-326 | 38-41 | 7.6 | 200 |

| 38EH | 1.22-1.25 | 12.2-12.5 | 2388 | 30 | 915 | 11.5 | 287-310 | 36-39 | 7.6 | 200 |

| 35EH | 1.17-1.22 | 11.7-12.2 | 2388 | 30 | 884 | 11.1 | 263-287 | 33-36 | 7.6 | 200 |

| 33EH | 1.13-1.17 | 11.3-11.7 | 2388 | 30 | 860 | 10.8 | 247-271 | 31-34 | 7.6 | 200 |

| 30EH | 1.08-1.13 | 10.8-11.3 | 2388 | 30 | 820 | 10.3 | 223-247 | 28-31 | 7.6 | 200 |

| 40AH | 1.25-1.28 | 12.5-12.8 | 2706 | 34 | 947 | 11.9 | 302-326 | 38-41 | 7.6 | 230 |

| 38AH | 1.22-1.25 | 12.2-12.5 | 2786 | 35 | 915 | 11.5 | 287-310 | 36-39 | 7.6 | 230 |

| 35AH | 1.17-1.2 | 11.7-12 | 2786 | 35 | 883 | 11.1 | 263-287 | 33-36 | 7.6 | 230 |

| 33AH | 1.11-1.17 | 11.1-11.7 | 2786 | 35 | 844 | 10.6 | 239-271 | 31-34 | 7.6 | 230 |

| 30AH | 1.07-1.13 | 10.7-11.3 | 2786 | 35 | 812 | 10.2 | 215-247 | 27-31 | 7.6 | 230 |

| 28AH | 1.02-1.09 | 10.2-10.9 | 2786 | 35 | 772 | 9.7 | 199-231 | 25-29 | 7.6 | 230 |

| 35TH | 1.17-1.22 | 11.7-12.2 | 3102 | 39 | 867 | 10.9 | 263-287 | 33-36 | 7.6 | 250 |

| 33TH | 1.11-1.17 | 11.1-11.7 | 3182 | 40 | 851 | 10.7 | 239-271 | 31-34 | 7.6 | 250 |

| 30TH | 1.08-1.13 | 10.8-11.3 | 3182 | 40 | 820 | 10.3 | 223-247 | 28-31 | 7.6 | 250 |

Physical Properties of sintered NdFeB

| Physical Properties of Sintered NdFeB | |

|---|---|

| Reversible Temp coeff. Of Br | -0.09~-0.11%/℃ |

| Reversible Temp coeff. Of Hcj | -0.45~-0.75%/℃ |

| Density | 7.4~7.7g/cm³ |

| Vickers Hardness | 500~600HV |

| Compressive Strength | 1000~1500MPa |

| Specific Heat | 0.12Kcal(Kg.℃) |

| Young Modulus | 150~200GPa |

| Poisson’s Ratio | 0.24 |

| Curie Temperature | 310~350℃ |

| Electrical Resistivity | 1.4~1.6μΩ·m |

| Tensile Strength | 80~90MPa |

| Coefficient of Thermal Expansion | (1-4)×10-6℃ |

| Pyroconductivity | 8~10W/(m.K) |

| Stiffness | 0.64N/m² |

| Compression Ratio | 9.8*10-12m2/N |

| Relative Permeability | 1.02~1.06 |

| Standard:GB/T 13560-2009 | |