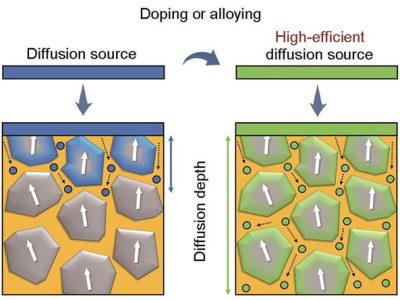

What is Ndfeb magnet diffusion process? Ndfeb magnet diffusion is a kind of NdFeb magnet manufacturing process, through a series of heating and cooling processes, the rare earth element neodymium and other elements are diffused into the magnet material to improve the magnetic properties and corrosion resistance of the magnet.

People have been committed to the development of technology to improve the performance of Ndfeb permanent magnet and reduce costs, in recent years, grain boundary diffusion technology (GBD) has received much attention and respect.

Before the advent of grain boundary diffusion technology, the main focus was to carry out composition optimization, such as the use of expensive heavy rare earths instead of light rare earths; Later, grain refinement was carried out to improve magnetic energy product and coercivity. Of course, grain boundary work is also being carried out, such as double alloy, double main phase process and so on.

The advantages and disadvantages of NdFeb comprehensive magnetic properties can be evaluated by the “magnetic energy product + coercive force” sum of this quality factor, after decades of efforts, the current magnetic energy product has been able to achieve close to the theoretical industrial level, in order to achieve more magnetic properties, engineers and technicians are mainly in coercive force. In recent years, the use of “cosmetic engineering” around the grain boundary diffusion technology has made the crystal phase structure and crystal phase composition of Ndfeb permanent magnet materials more beautiful, and more and more close to the ideal microstructure, so great progress has been made.

The current grain boundary diffusion technology has three major ways:

Cosmetic project 1: Improve the anisotropic field of the main phase boundary to improve coercivity

Cosmetic engineering two: Optimize the composition of grain boundary phase to improve coercivity

Cosmetic engineering three: Optimize the distribution structure and morphology of grain boundary phase to improve coercivity

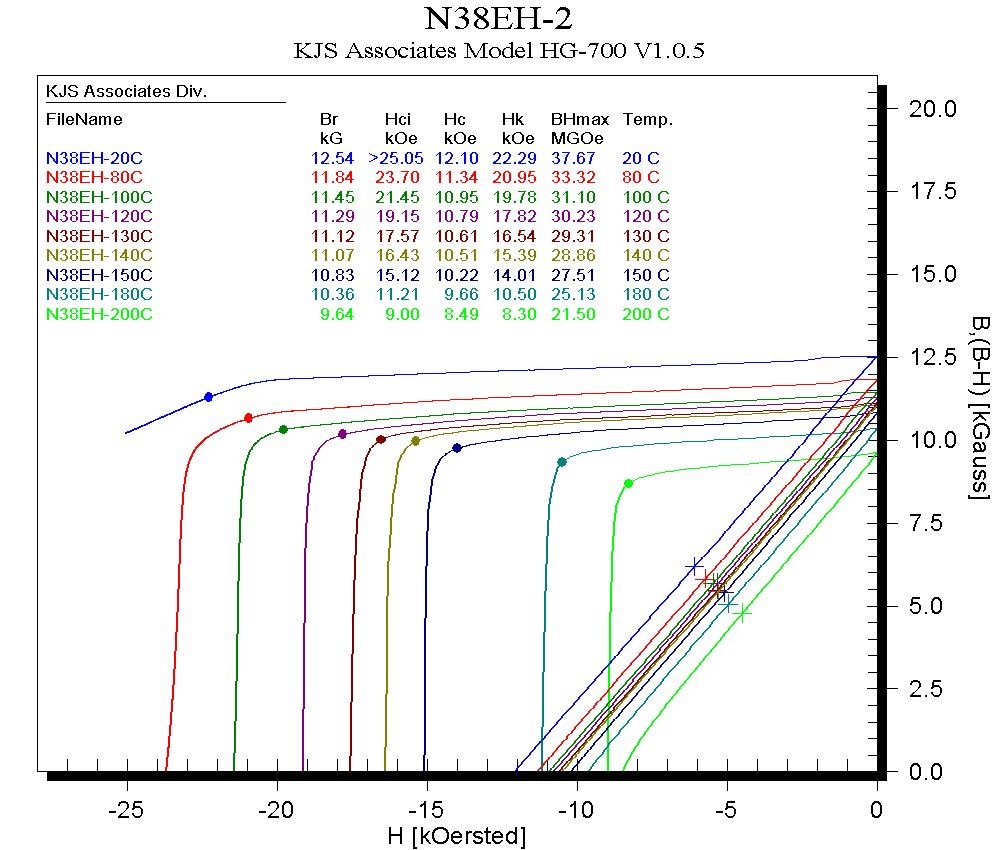

GBD process can not only improve coercive force, but also reduce the amount of heavy rare earth to reduce the cost of magnets. In recent years, GBD process has been used to supply high-end commercial magnets such as 50UH in fields such as permanent magnet motors for new energy vehicles, helping users improve the performance of terminal devices and reduce costs.

Although the Ndfeb magnet diffusion process is complex, high-performance and stable magnet materials can be obtained, which are widely used in motors, generators, electric vehicles, aerospace and other fields.