During the production process of magnets, it is inevitable that some corners or edges will be chipped, especially due to the brittle nature of the rare earth permanent magnet material itself. No matter how meticulous the processing is, some chipped corners will appear. So do the missing corners of these magnets have a big impact on the magnetic properties? Let’s discuss it together.

The impact of the missing angle of the magnet on the magnetic properties mainly depends on the size of the missing angle.

We know that the magnetic flux value of magnets of the same brand is proportional to the volume. If a certain specification of magnet is measured, the magnetic flux value of the intact magnet and the magnet with missing corners may be the same. Why is there such a result? This may be because the size of the defect is too small. The missing volume may be less than one thousandth of the volume of the magnet, and the impact on the magnetic flux value is minimal. Therefore, under normal circumstances, as long as the total missing volume is less than three thousandths of the magnet’s volume, there is no problem in the normal use of the magnet.

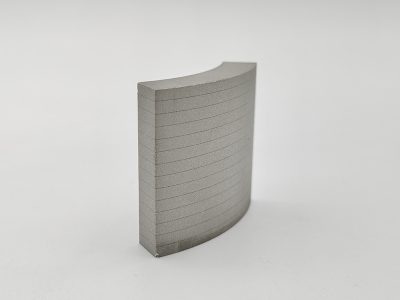

NdFeB permanent magnet materials and samarium cobalt permanent magnet materials are both brittle materials. It is normal for certain chipping and edge chipping to occur during the processing, including the mutual collision between the magnets and the stress caused by the processing to the magnets. Missing edges and corners. Of course, during the processing process, the unsightly areas are usually polished away through mechanical chamfering and vibration chamfering. Therefore, there will not be a particularly large proportion of missing edges or corners in the final product. (Except for products containing a large proportion of cerium, I will introduce NdFeB containing cerium when I have the opportunity)

So, what kind of missing corner standards are generally set?

For more precise products, it can be stipulated that the size of the missing corner shall not exceed 1/10 of the length, width and height of the magnet. It does not need to be particularly precise. The size of the missing corner shall not exceed 1/5 of the length, width and height of the magnet, or the total missing volume shall not exceed 1%.

For example, a D15.5x6 disc magnet with a chamfer of R0.6. The customer hopes that the delivery will be all perfect magnets, but the manufacturer says that in that case the price may need to increase by 20% because the pass rate is Not that high. Moreover, the magnetic properties and size of those small missing edges do not affect customer use. In the end, the two parties settled on a standard: the number of corners dropped in one piece of magnet should not exceed 2, each corner should not be larger than D1.5x1, and the proportion of corners dropped in the same batch should not be greater than 10%. In the end, everyone reached an agreement in this compromise way.

In fact, during the production process, the factory can increase the chamfering method to ensure the appearance yield. However, the magnetic flux loss increases after chamfering. So a compromise needs to be considered.

Rather than paying too much attention to the appearance of the magnet, it is better to pay more attention to the consistency of the magnetic properties of the magnet.

In the practical application of magnets, whether they are magnets used in motors or magnets used in instrument sensors, we need to pay attention to the consistency of magnetic flux in the same batch and the consistency between batches. Because many magnets that don’t look good in appearance have less than five thousandths of the total volume of missing corners, and the actual material performance deviation of the same batch of blanks can reach 1-3%, so the most important thing is the consistency of the material blanks. Stability can better ensure the consistency and stability of the finished product, and the final product can be stable.