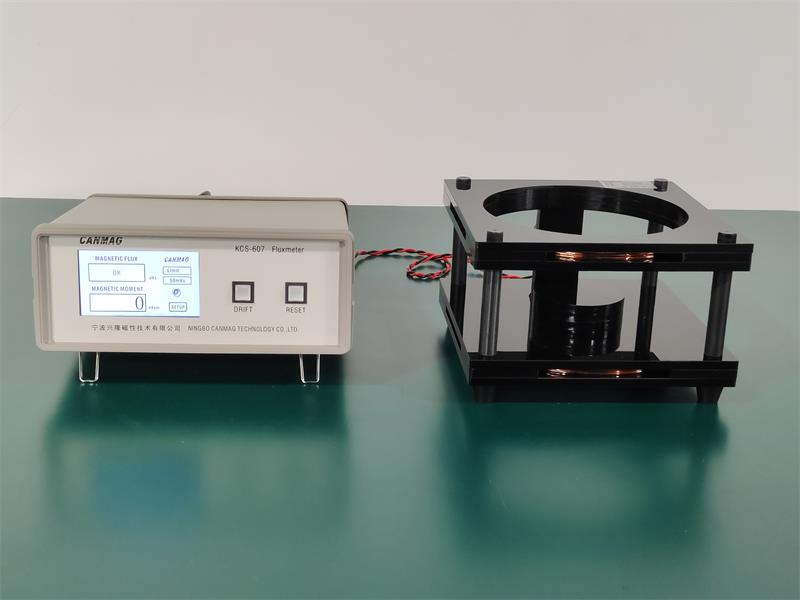

How to Determine the Magnetic Flux Consistency of Permanent Magnets

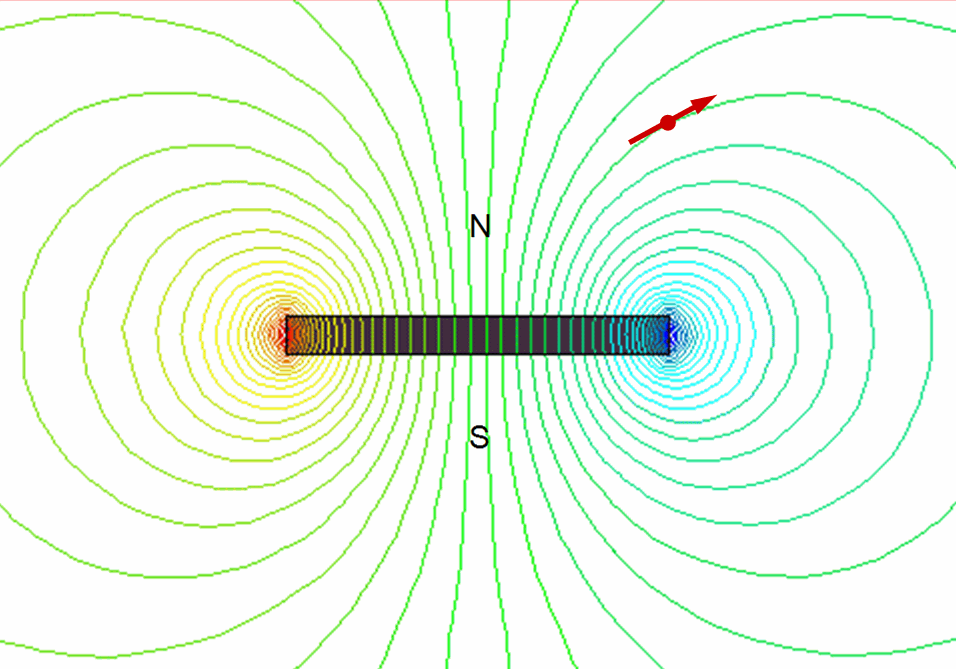

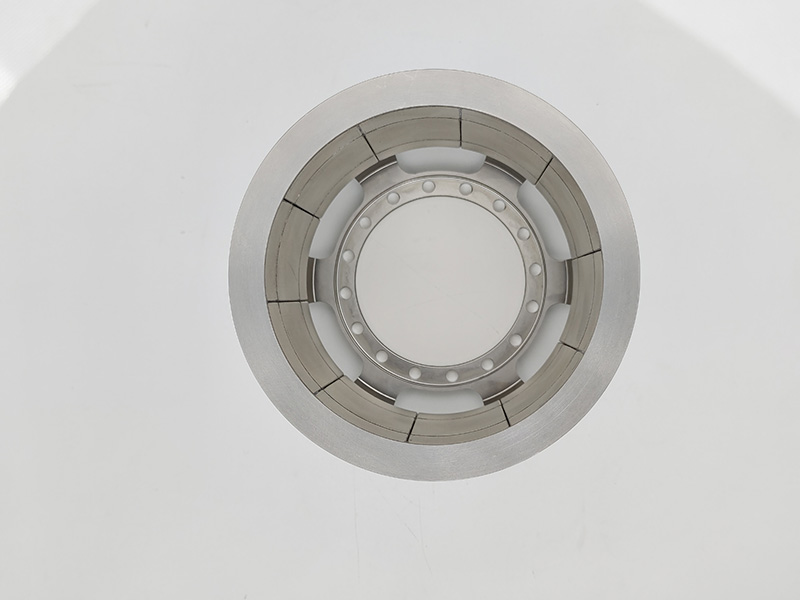

Determining the “magnetic flux consistency” (also known as “flux uniformity” or “homogeneity”) of permanent magnets is a key indicator for assessing the performance and quality of a batch of magnets or a magnet array. It refers to whether the magnetic flux output between different permanent magnet units, or at different positions of the same magnet, is consistent.